Auto parts manufacturers rely on frequent deliveries to vehicle production lines, demanding sustainable, reusable automotive packaging. These solutions must fit parts perfectly, ensure safe transport, and stay cost-effective. How do you pick the best option? This 2025 guide explores innovative packaging materials and expert tips to simplify your choice.

1. What Is Reusable Automotive Packaging?

Reusable automotive packaging powers efficient, eco-friendly transport for auto parts. Let’s break down its core concepts and benefits.

1.1 Concept: Reusable automotive packaging centers on two ideas:

- Reuse: Packaging designed for multiple trips or cycles within its lifespan.

- Recycling: Transforming waste materials into new products through sustainable processing (excluding energy recovery). In the auto parts industry, this includes dunnage and outer pallet box solutions, known as reusable automotive packaging.

1.2 Function: Reusable automotive packaging is tailored to fit auto parts perfectly, reducing damage during transport and handling. Beyond protection, it cuts costs and lowers carbon emissions, supporting a greener planet.

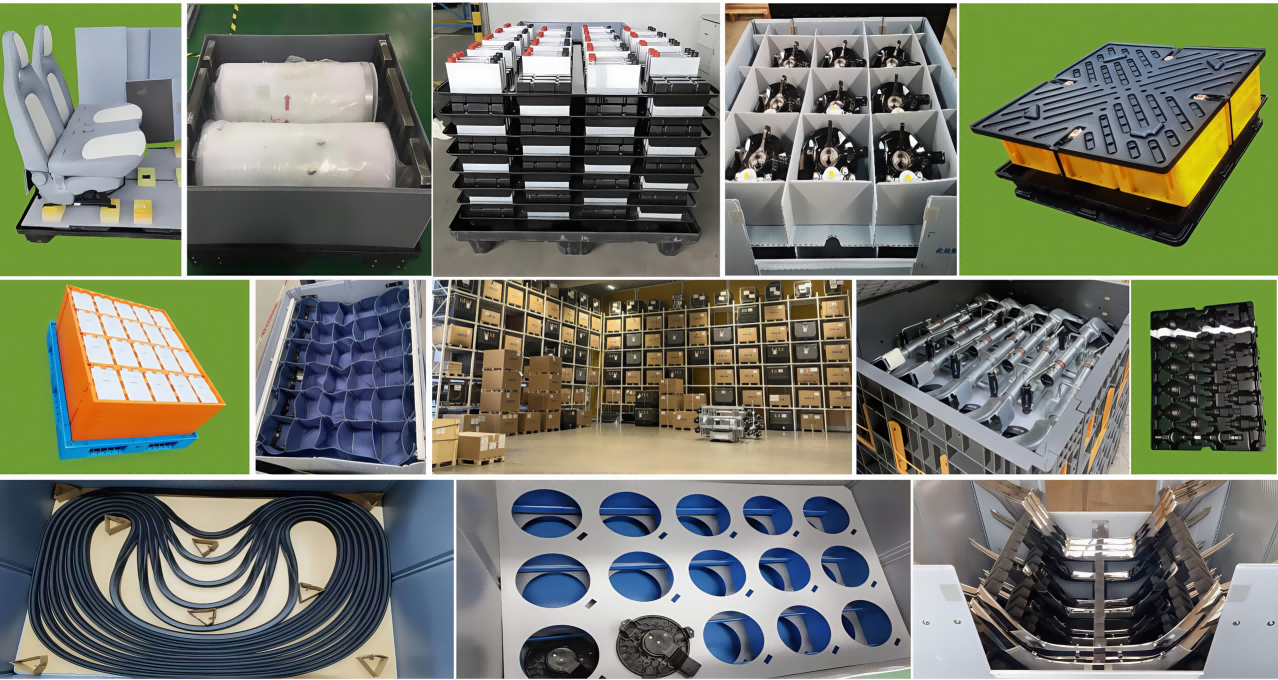

2. Types of Reusable Packaging in the Auto Parts Industry

From outer containers to inner liners, reusable packaging varies widely. Here’s a look at the top options for auto parts.

2.1 Outer Packaging Options

Durable outer packaging keeps auto parts secure across multiple trips. Key types include:

Sleeve Pack Boxes: Plastic, wooden, or corrugated cardboard options.

Pallet Boxes: Collapsible designs or bulk containers.

Metal Cages: Foldable, non-foldable, or rack styles.

Customized Pallet Boxes: Tailored sizes in plastic, wood, or metal.

Pallets: Plastic or steel for versatile use.

2.2 Inner Dunnage Packaging

Inner dunnage protects auto parts with precision. Popular options are:

Injection-Molded Packaging: Plastic boxes, EU boxes, and more.

Thermoformed Blister Trays: Custom-fit solutions.

Foam Packaging: EVA, EPP for cushioning.

Soft Materials: Non-woven fabrics, canvas, or Oxford fabric.

3. Auto Parts Types and Their Packaging Needs

Auto parts vary in size, weight, and fragility, driving unique packaging demands. This section outlines key types and the reusable solutions that protect them best.

3.1 Small Electronic Components

Small electronic parts, like sensors and wiring, need moisture-proof and anti-static packaging. Reusable options like ESD-safe injection-molded boxes keep them secure and functional.

3.2 Large Body Panels

Large body panels, such as doors or hoods, require anti-scratch and anti-warping protection. Soft liners like non-woven fabrics paired with sturdy sleeve pack boxes work best.

3.3 Powertrain Components

Powertrain parts—like engines or transmissions—demand corrosion protection, secure fit, and stacking strength. Reusable pallet boxes with foam inserts ensure safety and durability.

3.4 Fragile Auto Parts

Fragile parts, like headlights or glass, need anti-bumping, anti-movement, and anti-scratch packaging. Thermoformed blister trays and cushioned sleeve packs offer reliable protection.

4. Choosing the Best Automotive Packaging Solutions

With auto parts varying in size, shape, and material, packaging needs differ widely. How do you find the right reusable solution? We prioritize efficiency, energy savings, and cost-effectiveness in every design.

4.1 Engine Components

Engine components—like engines, pistons, cylinder heads, and crankshafts—need heavy-duty packaging. Reusable pallet containers with molded foam liners prevent shifting and corrosion.

4.2 Transmission System Components

Transmission parts, such as transmissions and drive axles, require secure, corrosion-resistant packaging. Collapsible pallet boxes with EVA foam ensure stability during transport.

4.3 Suspension System Components

Suspension parts—like shock absorbers, springs, stabilizer bars, and control arms—need robust packaging. Metal cages or sleeve packs with foam padding offer strength and flexibility.

4.4 Brake System Components

Brake parts, such as pads, rotors, fluid, master cylinders, and slave cylinders, demand precision packaging. Injection-molded boxes with anti-slip liners keep them safe and stackable.

4.5 Packaging Heavy Metal Parts

Engine, transmission, suspension, and brake components share a trait: most are heavy metal parts. Packaging must handle load capacity, prevent shifting, and resist corrosion. Here’s how:

Outer Solutions: Sleeve pack boxes, injection pallet containers, or custom pallet boxes.

Inner Liners: Thermoformed blister trays, plastic corrugated dividers, or molded foam.

These reusable options protect precision parts across multiple transport cycles, reducing damage risks. Customize liners to fit diverse shapes—like engines or axles—and add clear labels with QR codes for easy assembly.

4.6 Electrical Components

Electrical parts—like batteries, alternators, starters, and AC systems—need specialized packaging. Focus on anti-static, moisture-proof, and anti-vibration materials to protect fragile or heavy items like ECUs and motors. ESD-safe packaging is a must for sensitive electronics. With electric vehicles (EVs) like Tesla on the rise, battery packaging is key. Options include:

Inner Liners: Injection-molded EU boxes, thermoformed blister trays, or EVA/EPP foam.

Outer Containers: Plastic sleeve packs, injection pallet bins, or custom pallet boxes.

Tailor these reusable solutions to battery size and shape for safe, sustainable transport.

4.7 Interior Components

Interior parts—like seats, door panels, steering wheels, and instrument panels—vary in shape, size, and weight, requiring flexible packaging. Solutions include:

Seats: Corrugated boxes for direct packing.

Steering Wheels: Steel tubes in sleeve packs for stability.

Instrument Panels: Anti-slip film and foam in pallet boxes for shock protection.

These reusable designs cushion delicate parts like entertainment systems, ensuring safe delivery.

4.8 Tires and Rims

Tires, wheels, and rims need sturdy packaging for transport. Reusable options like pallets, pallet boxes, or metal containers cut costs, reduce carbon emissions, and boost sustainability in the auto parts industry.

4.9 Body Components

Body parts—like doors, automotive glass, roofs, headlights, and rearview mirrors—are large, lightweight, and fragile. Reusable packaging must prevent scratches and warping with:

Inner Liners: Soft, foldable materials like non-woven fabrics, foam, or fabric-lined plastic corrugated dividers.

Custom Fit: Thermoformed trays shaped to each part.

Outer Containers: Plastic sleeve boxes, injection pallet bins, or custom pallet boxes.

These solutions ensure safe, sustainable transport for delicate body components.

5. How to Pick the Best Automotive Packaging?

Choosing the right packaging for auto parts can be simple. Follow these steps to match solutions to your needs efficiently.

5.1 Define Your Goal

Start by deciding: single-use or reusable packaging?

Single-Use: Choose cardboard boxes or plastic bags for simplicity.

Reusable: Factor in part size, weight, transport distance, turnover frequency, and budget—opt for sleeve packs or pallet bins.

This step sets the foundation for cost-effective, sustainable choices.

5.2 Know Your Parts

Match packaging to your auto parts’ traits—size, weight, and fragility. Review the solutions above (e.g., foam for fragile glass, metal cages for heavy engines) to pick the best fit.

5.3 Design the Liner

Liners must fit auto parts’ shape, size, and weight to shield against impacts and vibrations. Design them for production line compatibility and easy securing, streamlining staff workflows.

5.4 Check Sizing

Ensure liner dimensions align with outer packaging and fit transport vehicles (e.g., containers or box trucks, typically 2.2–2.3m wide and 2.3m high). Design sleeve packs, pallet containers, and custom boxes with these limits in mind.

5.5 Select Materials

Choose liner materials based on auto parts’ needs:

Options: Plastic corrugated sheets, PP honeycomb, EVA/EPP foam, thermoformed blister trays, or cardboard—all excel at shock absorption.

Eco-Factor: Prioritize recyclable materials for sustainability.

For outer packaging, focus on load capacity and turnover with sleeve pack containers, pallet bins, or metal cages.

5.6 Add Markings

Seal and label outer boxes after securing parts. Include product name, model number, and production date for easy tracking and management.

In Summary: Partner for Success

Reusable automotive packaging demands expertise. Work closely with suppliers from the start—share part traits, packaging needs, turnover rates, and storage details. This ensures tailored, efficient solutions and avoids costly redesigns.